Defect detection in textured materials using Neural Networks

Various approaches based on texture analysis have been proposed for the automated visual inspection of textile webs. Computing features that capture texture properties is at the heart of most of these approaches. In this work a new approach to detect defects using feed-forward neural network (FFN) is investigated. Every fabric defect on textile web alters spatial arrangement of gray levels in the neighboring pixels and this change is used to detect the fabric defect. Every pixel from the acquired image is characterized by a feature vector. The gray level values of neighboring pixels form the feature vector for every pixel. The large dimension of feature vectors generates computational and overfitting problems. Therefore the dimension of feature vectors is reduced by using singular value decomposition of every feature vector. Further details from this work appears in a recent paper from Pattern Recognition.

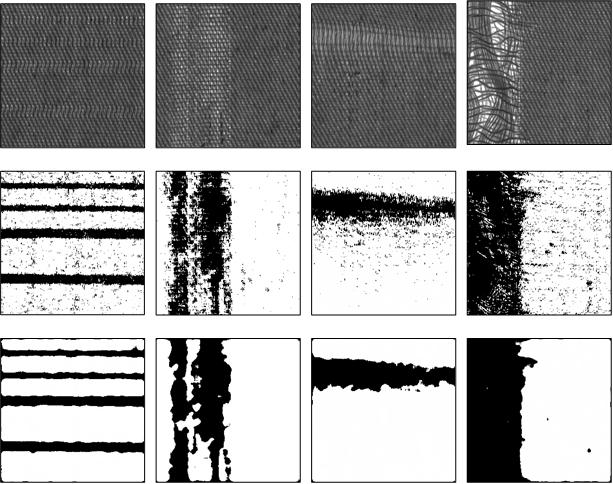

Figure 1: Twill weave fabric samples with defect mispick, netting-multilplies (1), thin bar, and netting-multiplies (2), and their corresponding segmentation of defects from 5/1 FFN.

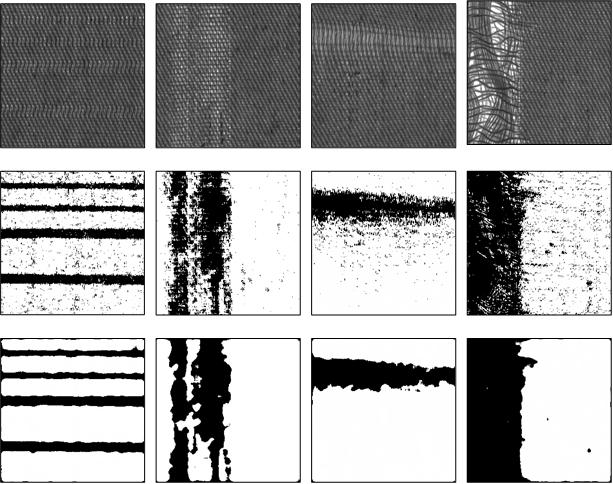

Figure 2: Convergence of training error from fabric defect mispick.

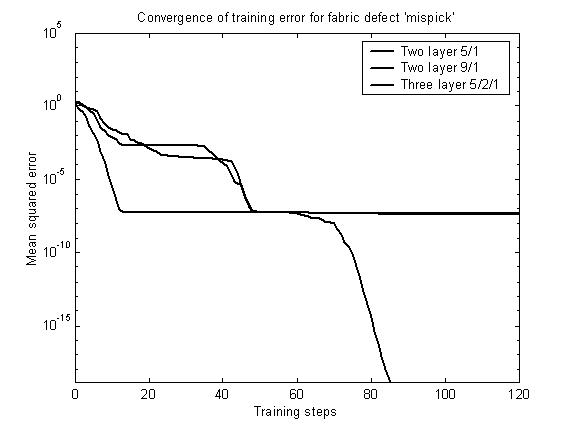

Figure 3: Plain weave fabric samples with defect double weft, thin bar, broken ends, sleck-pick and their corresponding segmentation of defects from 5/1 FFN.

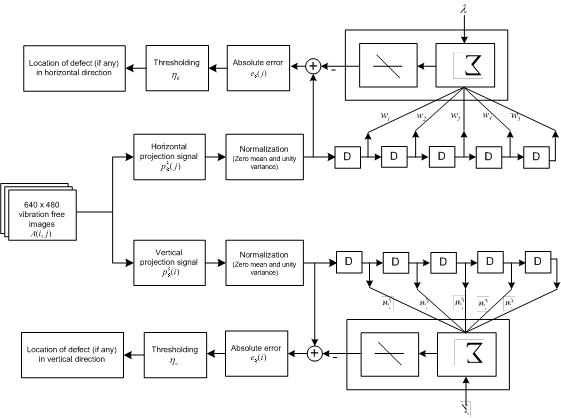

The computational simplicity is critical for success of any approach for real time fabric inspection. A low-cost solution for fabric defect detection using linear neural network was also proposed. Experimental results on the low-resolution images obtained from the real fabric samples have demonstrated their usefulness.

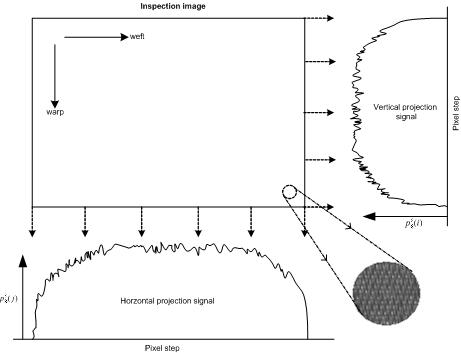

Figure 4: Generation of two projection signals from the image under inspection.

Figure 5: Block diagram of defect-detection scheme using linear neural networks.